about

about us

Welcome To

J.S Monndt International

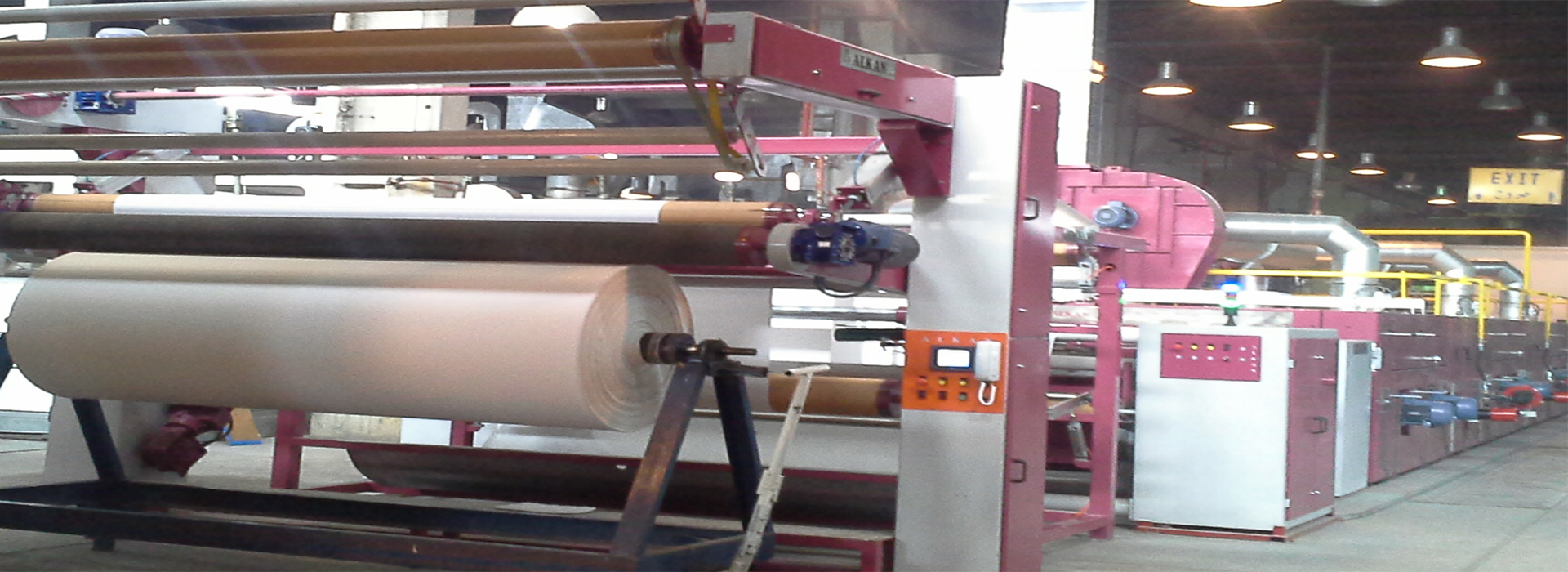

J.S Monndt International is one of the leading business houses for assisting composite textiles factories providing

high quality textile finishing machines essential spare parts and desired technical support in Bangladesh.

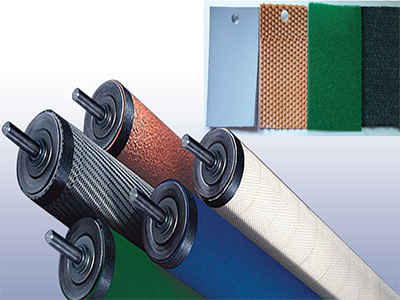

Our main products are Textile finishing machines such as Stenter, Dyeing, Printing, Dryer, Compactor, Raising,

Shearing & Sueiding machines and related spare parts with technical service support.

Our head office located in Germany from where we are able to supply you any with all kinds of Textile finishing machines and spare parts from world renowned brands as well as the brands we represent.

J.S Monndt International Machine brand includes ALKAN MAKINA (Stenter Machine) Turkey, GETABEC (Boiler) German-Thai Boiler Engineer Cooperation and world renowned Inverter & Motor producer LAEG, China.

See More